When you are thinking about a pneumatic power system for your upcoming projects, you might initially consider the traditional vane air motor. However, it is important to know that new advancements have introduced different technologies that could be a better fit for your specific needs.

What is a Piston Air Motor?

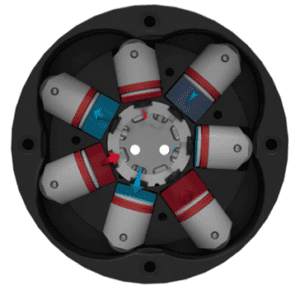

A piston air motor is a type of pneumatic motor that uses compressed air to create movement using pistons inside a cylinder.This motor operates by causing the pistons to move back and forth, converting this motion into circular movement through a crankshaft or other mechanisms.

Piston air motors exhibit the capacity to deliver robust torque at low speeds.. This makes them useful for tasks that need precise control and lifting heavy things.

The design of a piston air motor usually includes a container with the pistons, holes for air to come in and go out, and valves that manage the air to create the right movement. The air pressure pushes the pistons in opposite directions, making things turn around.

Piston air motors are good because they prove advantageous due to their reliability, simplicity, and suitability for hazardous environments where sparks or electricity might pose risks. Industries requiring robust performance, such as manufacturing, construction, mining, and marine operations, frequently opt for these motors.

Why Choose a Piston Motor?

Firstly, a piston motor has the same benefits as other pneumatic motors with a plain design. It has very few moving parts, which makes it reliable and easy to maintain. The plain design also means it lasts a long time and does not need a lot of downtime for repairs.

Further Read

- Have You Thought About Using a Piston Air Motor? Air Motors

- Piston Air Motors: Complete Guide to Working, Types, and Applications

- Air Motor Types Compared: Vane, Piston, Gear & Turbine

A piston motor is safe: One special thing about piston motors is that they are safe in explosive areas (ATEX). These motors do not make sparks when they work, which makes them great for places where safety is important.

Explore the different types of air motors and choose the right product for your needs, or contact us for more information.